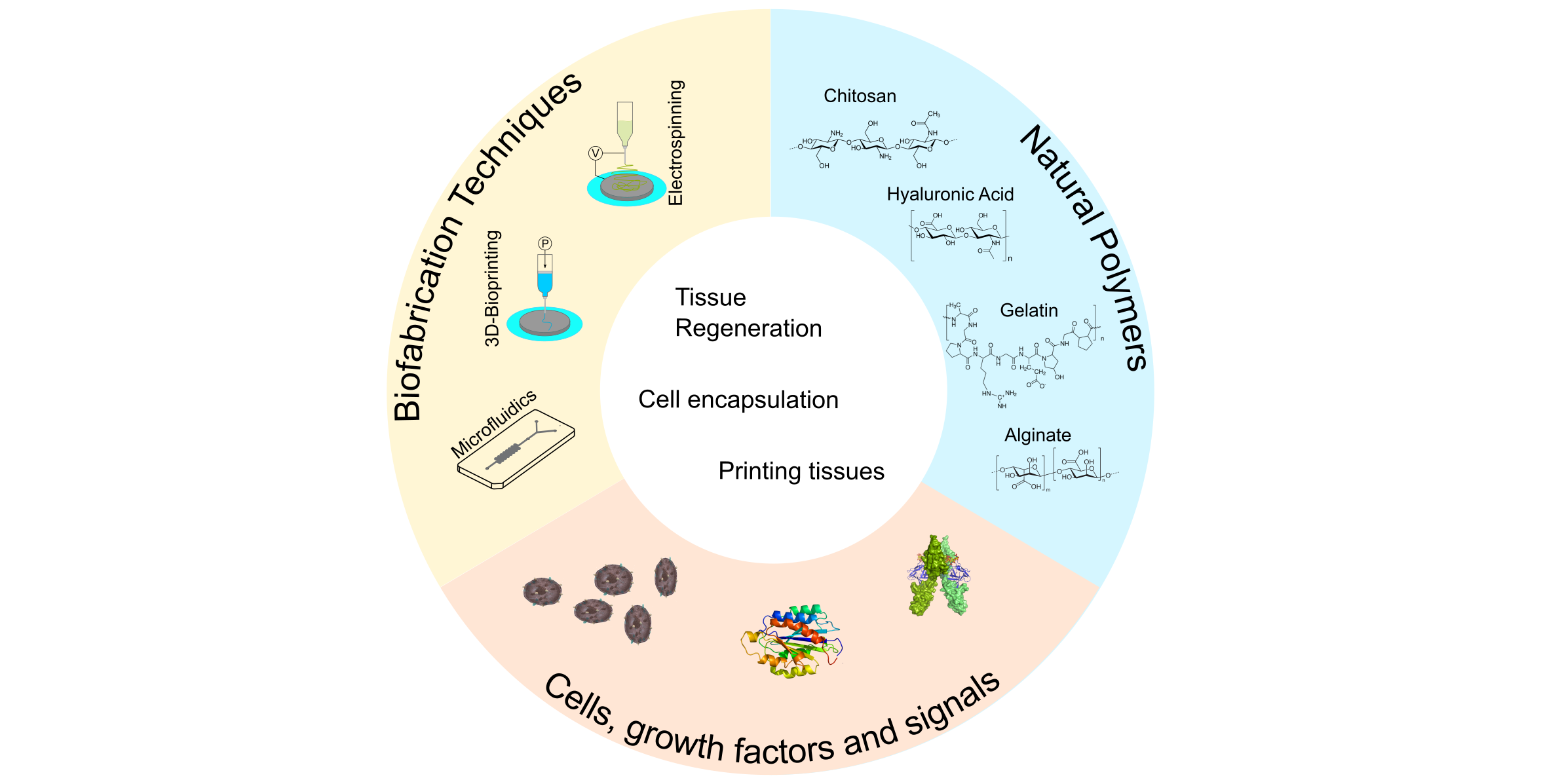

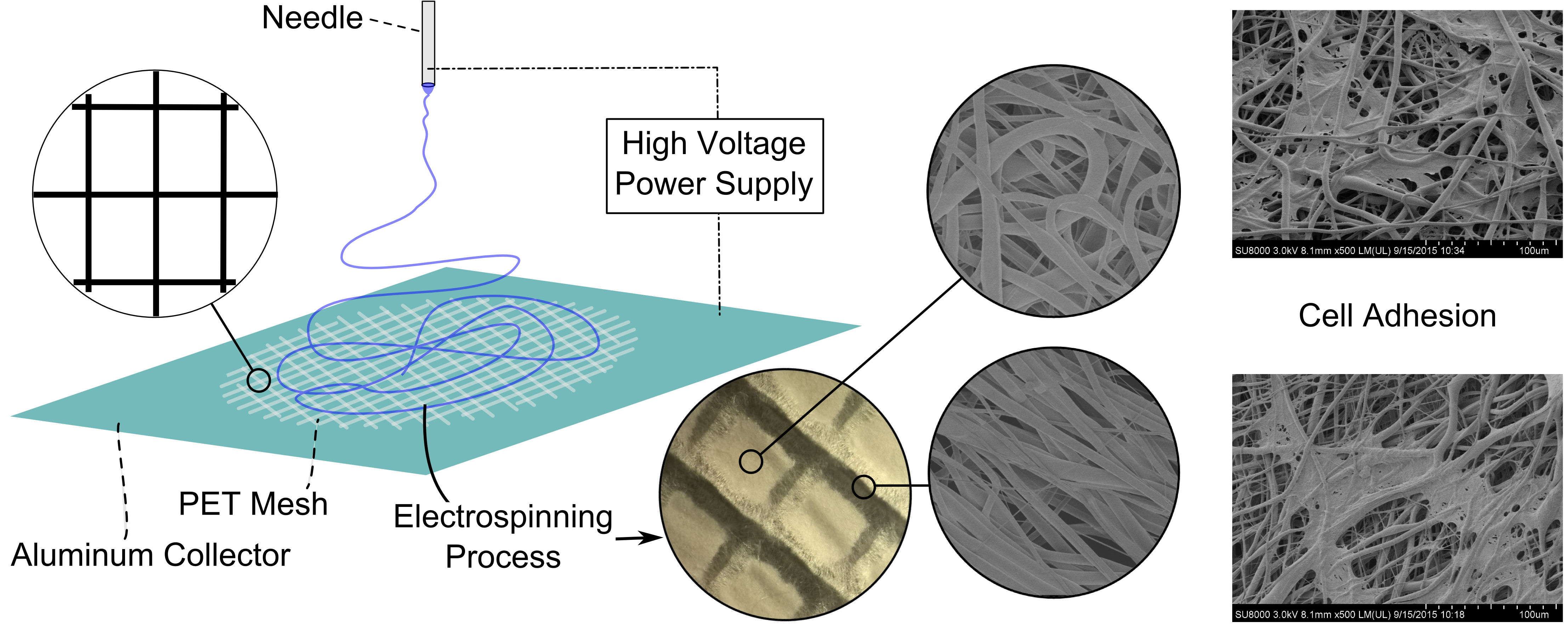

Natural polymers have been widely used for biomedical applications in recent decades. They offer the advantages of resembling the extracellular matrix of native tissues and retaining biochemical cues and properties necessary to enhance their biocompatibility, so they usually improve the cellular attachment and behavior and avoid immunological reactions. Moreover, they offer a rapid degradability through natural enzymatic or chemical processes. However, natural polymers present poor mechanical strength, which frequently makes the manipulation processes difficult. Recent advances in biofabrication, 3D printing, microfluidics, and cell-electrospinning allow the manufacturing of complex natural polymer matrixes with biophysical and structural properties similar to those of the extracellular matrix. In addition, these techniques offer the possibility of incorporating different cell lines into the fabrication process, a revolutionary strategy broadly explored in recent years to produce cell-laden scaffolds that can better mimic the properties of functional tissues. In this review, the use of 3D printing, microfluidics, and electrospinning approaches has been extensively investigated for the biofabrication of naturally derived polymer scaffolds with encapsulated cells intended for biomedical applications (e.g., cell therapies, bone and dental grafts, cardiovascular or musculoskeletal tissue regeneration, and wound healing).

3729048

{3729048:DRZ6DF7P}

nature

50

1

1

title

908

http://www.biomateriales.ictp.csic.es/wp-content/plugins/zotpress/

%7B%22status%22%3A%22success%22%2C%22updateneeded%22%3Afalse%2C%22instance%22%3A%22zotpress-17e9278ff2e2ec3661e16755bca9a8be%22%2C%22meta%22%3A%7B%22request_last%22%3A0%2C%22request_next%22%3A0%2C%22used_cache%22%3Atrue%7D%2C%22data%22%3A%5B%7B%22key%22%3A%22DRZ6DF7P%22%2C%22library%22%3A%7B%22id%22%3A3729048%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Puertas-Bartolom%5Cu00e9%20et%20al.%22%2C%22parsedDate%22%3A%222021-01%22%2C%22numChildren%22%3A2%7D%2C%22bib%22%3A%22%3Cdiv%20class%3D%5C%22csl-bib-body%5C%22%20style%3D%5C%22line-height%3A%202%3B%20%5C%22%3E%5Cn%20%3Cdiv%20class%3D%5C%22csl-entry%5C%22%20style%3D%5C%22clear%3A%20left%3B%20%5C%22%3E%5Cn%20%3Cdiv%20class%3D%5C%22csl-left-margin%5C%22%20style%3D%5C%22float%3A%20left%3B%20padding-right%3A%200.5em%3B%20text-align%3A%20right%3B%20width%3A%201em%3B%5C%22%3E1.%3C%5C%2Fdiv%3E%3Cdiv%20class%3D%5C%22csl-right-inline%5C%22%20style%3D%5C%22margin%3A%200%20.4em%200%201.5em%3B%5C%22%3EPuertas-Bartolom%5Cu00e9%2C%20M.%2C%20Mora-Boza%2C%20A.%20%26%20Garc%5Cu00eda-Fern%5Cu00e1ndez%2C%20L.%20%3Ca%20target%3D%27_blank%27%20href%3D%27https%3A%5C%2F%5C%2Fwww.mdpi.com%5C%2F2073-4360%5C%2F13%5C%2F8%5C%2F1209%27%3EEmerging%20Biofabrication%20Techniques%3A%20A%20Review%20on%20Natural%20Polymers%20for%20Biomedical%20Applications%3C%5C%2Fa%3E.%20%3Ci%3EPolymers%3C%5C%2Fi%3E%20%3Cb%3E13%3C%5C%2Fb%3E%2C%201209%20%282021%29.%20%3Ca%20title%3D%27Cite%20in%20RIS%20Format%27%20class%3D%27zp-CiteRIS%27%20href%3D%27http%3A%5C%2F%5C%2Fwww.biomateriales.ictp.csic.es%5C%2Fwp-content%5C%2Fplugins%5C%2Fzotpress%5C%2Flib%5C%2Frequest%5C%2Frequest.cite.php%3Fapi_user_id%3D3729048%26amp%3Bitem_key%3DDRZ6DF7P%27%3ECite%3C%5C%2Fa%3E%20%3C%5C%2Fdiv%3E%5Cn%20%3C%5C%2Fdiv%3E%5Cn%3C%5C%2Fdiv%3E%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Emerging%20Biofabrication%20Techniques%3A%20A%20Review%20on%20Natural%20Polymers%20for%20Biomedical%20Applications%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Mar%5Cu00eda%22%2C%22lastName%22%3A%22Puertas-Bartolom%5Cu00e9%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Ana%22%2C%22lastName%22%3A%22Mora-Boza%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Luis%22%2C%22lastName%22%3A%22Garc%5Cu00eda-Fern%5Cu00e1ndez%22%7D%5D%2C%22abstractNote%22%3A%22Natural%20polymers%20have%20been%20widely%20used%20for%20biomedical%20applications%20in%20recent%20decades.%20They%20offer%20the%20advantages%20of%20resembling%20the%20extracellular%20matrix%20of%20native%20tissues%20and%20retaining%20biochemical%20cues%20and%20properties%20necessary%20to%20enhance%20their%20biocompatibility%2C%20so%20they%20usually%20improve%20the%20cellular%20attachment%20and%20behavior%20and%20avoid%20immunological%20reactions.%20Moreover%2C%20they%20offer%20a%20rapid%20degradability%20through%20natural%20enzymatic%20or%20chemical%20processes.%20However%2C%20natural%20polymers%20present%20poor%20mechanical%20strength%2C%20which%20frequently%20makes%20the%20manipulation%20processes%20difficult.%20Recent%20advances%20in%20biofabrication%2C%203D%20printing%2C%20microfluidics%2C%20and%20cell-electrospinning%20allow%20the%20manufacturing%20of%20complex%20natural%20polymer%20matrixes%20with%20biophysical%20and%20structural%20properties%20similar%20to%20those%20of%20the%20extracellular%20matrix.%20In%20addition%2C%20these%20techniques%20offer%20the%20possibility%20of%20incorporating%20different%20cell%20lines%20into%20the%20fabrication%20process%2C%20a%20revolutionary%20strategy%20broadly%20explored%20in%20recent%20years%20to%20produce%20cell-laden%20scaffolds%20that%20can%20better%20mimic%20the%20properties%20of%20functional%20tissues.%20In%20this%20review%2C%20the%20use%20of%203D%20printing%2C%20microfluidics%2C%20and%20electrospinning%20approaches%20has%20been%20extensively%20investigated%20for%20the%20biofabrication%20of%20naturally%20derived%20polymer%20scaffolds%20with%20encapsulated%20cells%20intended%20for%20biomedical%20applications%20%28e.g.%2C%20cell%20therapies%2C%20bone%20and%20dental%20grafts%2C%20cardiovascular%20or%20musculoskeletal%20tissue%20regeneration%2C%20and%20wound%20healing%29.%22%2C%22date%22%3A%222021%5C%2F1%22%2C%22language%22%3A%22en%22%2C%22DOI%22%3A%2210.3390%5C%2Fpolym13081209%22%2C%22ISSN%22%3A%22%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fwww.mdpi.com%5C%2F2073-4360%5C%2F13%5C%2F8%5C%2F1209%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222021-04-12T11%3A41%3A52Z%22%7D%7D%5D%7D