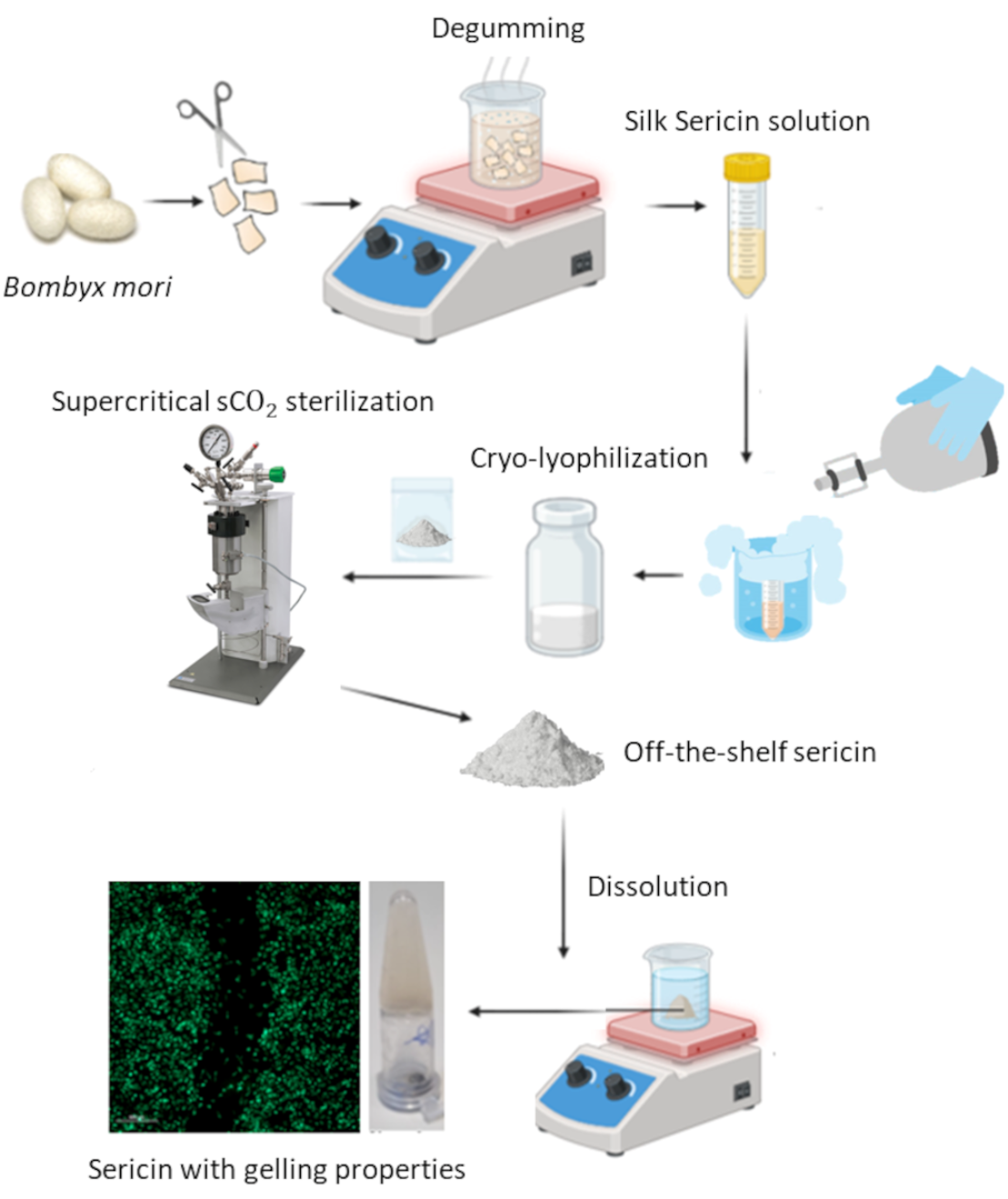

Silk sericin (SS), a by-product of the textile industry, has gained significant attention for its biomedical potential due to its biocompatibility and regenerative potential. However, the literature lacks information on SS processing methods and the resulting physicochemical properties. This study represents the first step in protocol optimization and standardization. In the present work, different processing techniques were studied and compared on SS extracted from boiling water: evaporation, rotary evaporation, lyophilization, and dialysis, which presented a recovery yield of approximately 27–32%. The goal was to find the most promising process to concentrate extracted SS solutions, and to ensure that the SS structure was highly preserved. As a result, a new cryo-lyophilization methodology was proposed. The proposed method allows for the preservation of the amorphous structure, which offers significant advantages including complete dissolution in water and PBS, an increase in storage stability, and the possibility of scaling-up, making it highly suitable for industrial and biomedical applications. The second part of the work focused on addressing another challenge in SS processing: efficient and non-destructive sterilization. Supercritical CO2 (scCO2) has been gaining momentum in the last years for sterilizing sensitive biopolymers and biological materials due to its non-toxicity and mild processing conditions. Thus, scCO2 technology was validated as a mild technique for the terminal sterilization of SS. In this way, it was possible to engineer a sequential cryo-lyophilization/scCO2 sterilization process which was able to preserve the original properties of this natural silk protein. Overall, we have valorized SS into a sterile, off-the-shelf, bioactive, and water-soluble material, with the potential to be used in the biomedical, pharmaceutical, or cosmetic industries.

3729048

{3729048:XDZUWTLX}

1

nature

50

default

1

1

1855

http://www.biomateriales.ictp.csic.es/wp-content/plugins/zotpress/

%7B%22status%22%3A%22success%22%2C%22updateneeded%22%3Afalse%2C%22instance%22%3Afalse%2C%22meta%22%3A%7B%22request_last%22%3A0%2C%22request_next%22%3A0%2C%22used_cache%22%3Atrue%7D%2C%22data%22%3A%5B%7B%22key%22%3A%22XDZUWTLX%22%2C%22library%22%3A%7B%22id%22%3A3729048%7D%2C%22meta%22%3A%7B%22creatorSummary%22%3A%22Veiga%20et%20al.%22%2C%22parsedDate%22%3A%222025-02%22%2C%22numChildren%22%3A1%7D%2C%22bib%22%3A%22%3Cdiv%20class%3D%5C%22csl-bib-body%5C%22%20style%3D%5C%22line-height%3A%202%3B%20%5C%22%3E%5Cn%20%20%3Cdiv%20class%3D%5C%22csl-entry%5C%22%20style%3D%5C%22clear%3A%20left%3B%20%5C%22%3E%5Cn%20%20%20%20%3Cdiv%20class%3D%5C%22csl-left-margin%5C%22%20style%3D%5C%22float%3A%20left%3B%20padding-right%3A%200.5em%3B%20text-align%3A%20right%3B%20width%3A%201em%3B%5C%22%3E1.%3C%5C%2Fdiv%3E%3Cdiv%20class%3D%5C%22csl-right-inline%5C%22%20style%3D%5C%22margin%3A%200%20.4em%200%201.5em%3B%5C%22%3EVeiga%2C%20A.%20%3Ci%3Eet%20al.%3C%5C%2Fi%3E%20Innovative%20Processing%20and%20Sterilization%20Techniques%20to%20Unlock%20the%20Potential%20of%20Silk%20Sericin%20for%20Biomedical%20Applications.%20%3Ci%3EGels%3C%5C%2Fi%3E%20%3Cb%3E11%3C%5C%2Fb%3E%2C%20114%20%282025%29.%20%3Ca%20title%3D%27Cite%20in%20RIS%20Format%27%20class%3D%27zp-CiteRIS%27%20href%3D%27http%3A%5C%2F%5C%2Fwww.biomateriales.ictp.csic.es%5C%2Fwp-content%5C%2Fplugins%5C%2Fzotpress%5C%2Flib%5C%2Frequest%5C%2Frequest.cite.php%3Fapi_user_id%3D3729048%26amp%3Bitem_key%3DXDZUWTLX%27%3ECite%3C%5C%2Fa%3E%20%20%3Ca%20title%3D%27Download%27%20class%3D%27zp-DownloadURL%27%20href%3D%27http%3A%5C%2F%5C%2Fwww.biomateriales.ictp.csic.es%5C%2Fwp-content%5C%2Fplugins%5C%2Fzotpress%5C%2Flib%5C%2Frequest%5C%2Frequest.dl.php%3Fapi_user_id%3D3729048%26amp%3Bdlkey%3DM6S6K6PE%26amp%3Bcontent_type%3Dapplication%5C%2Fpdf%27%3EDownload%3C%5C%2Fa%3E%3C%5C%2Fdiv%3E%5Cn%20%20%3C%5C%2Fdiv%3E%5Cn%3C%5C%2Fdiv%3E%22%2C%22data%22%3A%7B%22itemType%22%3A%22journalArticle%22%2C%22title%22%3A%22Innovative%20Processing%20and%20Sterilization%20Techniques%20to%20Unlock%20the%20Potential%20of%20Silk%20Sericin%20for%20Biomedical%20Applications%22%2C%22creators%22%3A%5B%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Anabela%22%2C%22lastName%22%3A%22Veiga%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Rosa%20Ana%22%2C%22lastName%22%3A%22Ram%5Cu00edrez-Jim%5Cu00e9nez%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22V%5Cu00edctor%22%2C%22lastName%22%3A%22Santos-Rosales%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Carlos%20A.%22%2C%22lastName%22%3A%22Garc%5Cu00eda-Gonz%5Cu00e1lez%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Maria%20Rosa%22%2C%22lastName%22%3A%22Aguilar%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Luis%22%2C%22lastName%22%3A%22Rojo%22%7D%2C%7B%22creatorType%22%3A%22author%22%2C%22firstName%22%3A%22Ana%20L.%22%2C%22lastName%22%3A%22Oliveira%22%7D%5D%2C%22abstractNote%22%3A%22Silk%20sericin%20%28SS%29%2C%20a%20by-product%20of%20the%20textile%20industry%2C%20has%20gained%20significant%20attention%20for%20its%20biomedical%20potential%20due%20to%20its%20biocompatibility%20and%20regenerative%20potential.%20However%2C%20the%20literature%20lacks%20information%20on%20SS%20processing%20methods%20and%20the%20resulting%20physicochemical%20properties.%20This%20study%20represents%20the%20first%20step%20in%20protocol%20optimization%20and%20standardization.%20In%20the%20present%20work%2C%20different%20processing%20techniques%20were%20studied%20and%20compared%20on%20SS%20extracted%20from%20boiling%20water%3A%20evaporation%2C%20rotary%20evaporation%2C%20lyophilization%2C%20and%20dialysis%2C%20which%20presented%20a%20recovery%20yield%20of%20approximately%2027%5Cu201332%25.%20The%20goal%20was%20to%20find%20the%20most%20promising%20process%20to%20concentrate%20extracted%20SS%20solutions%2C%20and%20to%20ensure%20that%20the%20SS%20structure%20was%20highly%20preserved.%20As%20a%20result%2C%20a%20new%20cryo-lyophilization%20methodology%20was%20proposed.%20The%20proposed%20method%20allows%20for%20the%20preservation%20of%20the%20amorphous%20structure%2C%20which%20offers%20significant%20advantages%20including%20complete%20dissolution%20in%20water%20and%20PBS%2C%20an%20increase%20in%20storage%20stability%2C%20and%20the%20possibility%20of%20scaling-up%2C%20making%20it%20highly%20suitable%20for%20industrial%20and%20biomedical%20applications.%20The%20second%20part%20of%20the%20work%20focused%20on%20addressing%20another%20challenge%20in%20SS%20processing%3A%20efficient%20and%20non-destructive%20sterilization.%20Supercritical%20CO2%20%28scCO2%29%20has%20been%20gaining%20momentum%20in%20the%20last%20years%20for%20sterilizing%20sensitive%20biopolymers%20and%20biological%20materials%20due%20to%20its%20non-toxicity%20and%20mild%20processing%20conditions.%20Thus%2C%20scCO2%20technology%20was%20validated%20as%20a%20mild%20technique%20for%20the%20terminal%20sterilization%20of%20SS.%20In%20this%20way%2C%20it%20was%20possible%20to%20engineer%20a%20sequential%20cryo-lyophilization%5C%2FscCO2%20sterilization%20process%20which%20was%20able%20to%20preserve%20the%20original%20properties%20of%20this%20natural%20silk%20protein.%20Overall%2C%20we%20have%20valorized%20SS%20into%20a%20sterile%2C%20off-the-shelf%2C%20bioactive%2C%20and%20water-soluble%20material%2C%20with%20the%20potential%20to%20be%20used%20in%20the%20biomedical%2C%20pharmaceutical%2C%20or%20cosmetic%20industries.%22%2C%22date%22%3A%222025%5C%2F2%22%2C%22language%22%3A%22en%22%2C%22DOI%22%3A%2210.3390%5C%2Fgels11020114%22%2C%22ISSN%22%3A%222310-2861%22%2C%22url%22%3A%22https%3A%5C%2F%5C%2Fwww.mdpi.com%5C%2F2310-2861%5C%2F11%5C%2F2%5C%2F114%22%2C%22collections%22%3A%5B%5D%2C%22dateModified%22%3A%222025-02-06T12%3A06%3A55Z%22%7D%7D%5D%7D

1.

Veiga, A.

et al. Innovative Processing and Sterilization Techniques to Unlock the Potential of Silk Sericin for Biomedical Applications.

Gels 11, 114 (2025).

Cite Download